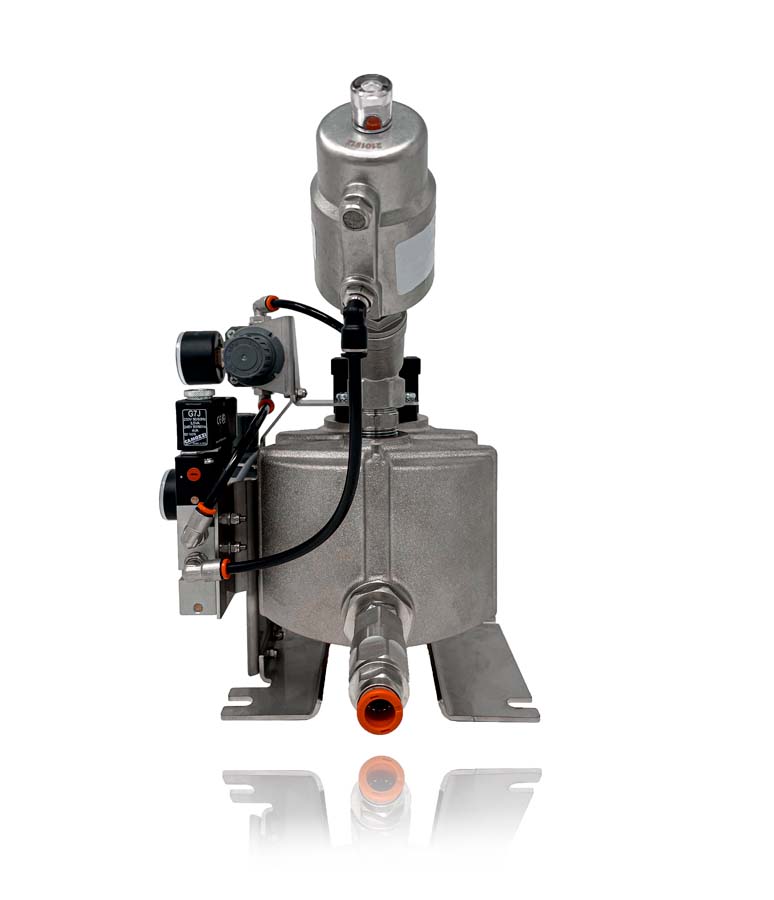

Vacuum Drain

Vacuum Drain is an automatic condensate drain system specially designed for vacuum plants, in order to be a reliable solution to support vacuum applications.

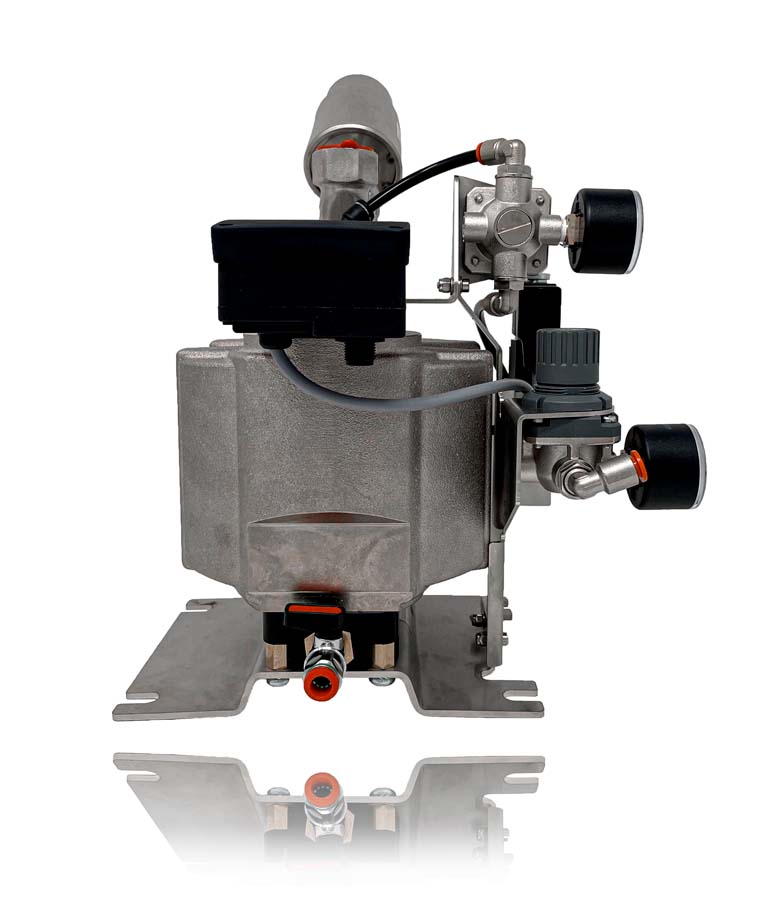

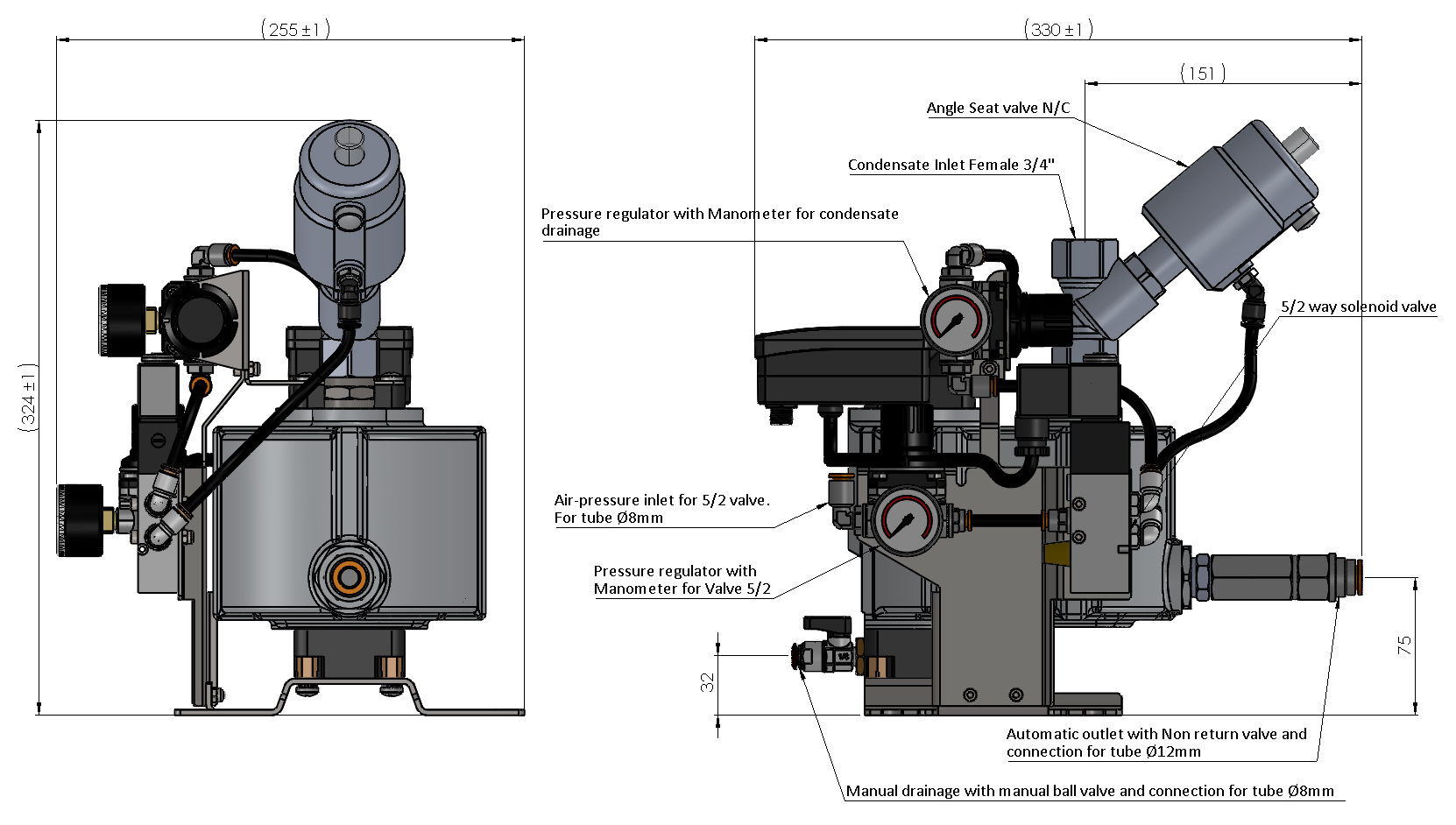

During the condensate dripping phase, the non-return valve at the outlet is closed thanks to the vacuum conditions created inside the receiver, which is at the same pressure as the vacuum system. When the Vacuum Drain receiver reaches the maximum accumulation level, the electronics command the closure of the piston valve and, thanks to the 5/2 valve, the 4bar service pressure allows a quick drain of the condensate from the non-return valve. When the condensate level returns to the minimum, the 5/2 valve opens the piston valve, while the non-return valve closes to repeat the cycle.

In case of non-discharge of the condensate, Vacuum Drain activates a sequence of forced drains to try to resolve the suffering situation. During this sequence, the red LED on the control panel flashes and an alarm signal is sent outside. A ball valve for manual discharge represents a further versatile solution for service activities.

| 230 V AC | 115 V AC | 24 V AC | |

|---|---|---|---|

| Power supply (±10%) | 230 V (50/60Hz) | 115 V (50/60Hz) | 24 V AC(50/60Hz) |

| Power consumption (during drainage) | 4 VA | 4 VA | |

| Working pressure | 0,1-1,8 bar (abs) | ||

| Working temperature | +1/+60 °C | ||

| Protection class | IP65 (with power supply connector correctly mounted) | ||

| Alarm connection | M12 Code A 4 Poles (Not supplied) | ||

| Electrical connection | EN 175301-803 Type B (ex DIN 43650) (Supplied) | ||

| Nominal flow | 30lt/h @4bar (g) | ||

| Single Draining | 0,5lt/h @4bar (g) | ||

| Maximum performance | 60lt/h @4bar (g) | ||

| Pressure to operate the 5/2way valve | 4bar | ||

| Pressure to ensure open/close angle seat valve | 2bar | ||

| Inlet | 1xG¾” F | ||

| Outlet | 1 x ø12 | ||

| Weight (Kg) | 5,1 | ||

| Receiver volume (liter) | 1,5 | ||

| Certificates | CE + UKCA | ||

| Code | 20-661 | 20-662 | 20-663 |